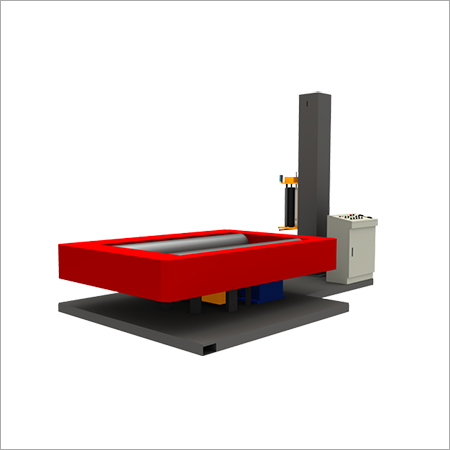

Reel Stretch Wrapping Machine

Product Details:

- Product Type Reel Stretch Wrapping Machine

- Material Mild Steel

- Capacity Up to 30 Reels/Hour

- Computerized No

- Automatic Grade Semi-Automatic

- Voltage 220/380 V

- Power 2.5 kW

- Click to View more

Reel Stretch Wrapping Machine Price And Quantity

Reel Stretch Wrapping Machine Product Specifications

- Semi-Automatic

- Adjustable, 2-8 m/min

- 220/380 V

- 10-55% Adjustable

- Up to 30 Reels/Hour

- No

- 2.5 kW

- Up to 12 rpm

- Mild Steel

- 2100 mm x 1350 mm x 2100 mm

- Approx. 700 kg

- Industrial Grey with Yellow Accents

- Customizable, Standard 1800 mm

- Reel Stretch Wrapping Machine

Product Description

Durapak Reel Wrapper is a machine that is planned for packing rolls non-woven fabrics, film, paper and kindred products made in rolls. It is perfect for reel axial covering-across the cylindric diameter then along the longitudinal axis of rotation. We offer the ideal wrapper for reel type products so as to attain moisture and dust proof quality and increased packing effects for storage and transport. Alternatives: ejection system, pneumatic reel or fully automated conveyorized reel wrapper.

Features:

- High-powered pre-stretch film equipage, ratio 250%.

- Automated wrapping in accordance with pre-set parameters. Friendly user program for setting film tension and wrap cycles.

- Turntable home position, auto height detection, forklift cavum for simple moving.

- Roller speed changeable through the inverter.

- Double limit switches on top & bottom to give improved safety protections.

Technical Specification:

| Wrapping size | L(500-1500)mm, W(500-1600)mm. |

| Packing Speed | 20-40 per hour. |

| Loading Weight | 2000kg. |

| Turntable Speed | 0-150rpm, speed variable, turntable soft start & soft sotp |

| Carriage Speed | 3m/min. |

| Working Mode | automatic |

| Power | 3PH280VAC, 50/60Hz,20A, 3.4Kw. |

Advanced Wrapping Efficiency

This machine streamlines reel packaging by utilizing a powered pre-stretch carriage and a PLC-based digital panel, ensuring consistent tension and film usage. The adjustable overlap (10-55%) and variable shift speeds (2-8 m/min) cater to diverse wrapping requirements, optimizing productivity.

Built for Safety and Reliability

Designed with operator safety in mind, the unit includes emergency stop functions and interlocking guards. Its mild steel construction and robust turntable (1650 mm diameter) provide excellent stability for handling reels up to 1000 kg, ensuring years of reliable operation.

Versatility Across Industries

Suitable for paper, film, textile, and tyre reels, this machine fits varied operational spaces due to its customizable conveyor length and compact footprint of 2100 mm x 1350 mm x 2100 mm. Its capacity to handle up to 30 reels per hour makes it a valuable asset for high-volume manufacturers.

FAQs of Reel Stretch Wrapping Machine:

Q: How does the powered pre-stretch film carriage improve the wrapping process?

A: The powered pre-stretch film carriage ensures optimal film tension and uniform application by stretching the LLDPE film before it is applied. This results in reduced film consumption and enhanced load stability during storage or transportation.Q: What kind of reels can this machine wrap, and what are the maximum specifications?

A: The machine is capable of wrapping paper, film, textile, and tyre reels with a maximum diameter of 1200 mm, width up to 1600 mm, and weight up to 1000 kg, accommodating various industry needs.Q: When should you opt for this reel stretch wrapping machine in your production line?

A: You should choose this machine when handling moderate to large quantities (up to 30 reels/hour) of heavy or wide reels, particularly if your workflow requires consistent wrapping quality, operator safety, and adjustable wrapping parameters.Q: Where is this machine typically installed, and what installation requirements should be considered?

A: This machine is commonly installed in manufacturing plants or distribution centers, especially where reel products require protective wrapping. It operates on 220/380 V power, occupies a footprint of 2100 mm x 1350 mm, and requires a stable surface for safety and performance.Q: What does the PLC-based digital control panel offer to users?

A: The PLC-based control panel provides intuitive operation, enabling the user to easily adjust parameters such as overlap percentage, shift speed, and wrapping cycles for different reel types, enhancing overall operational control.Q: How does the emergency stop and interlocking guard system contribute to operator safety?

A: The emergency stop shuts down the machine instantly in case of an incident, while the interlocking guard prevents access to moving parts during operation, collectively ensuring a safe working environment for operators.Q: What are the main benefits of using an LLDPE stretch film with thicknesses between 17-35 microns on this machine?

A: Using LLDPE stretch film within this thickness range offers a balance of strength and flexibility, protecting reels against moisture and dust while minimizing film breakage or excess material consumption.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free