Automatic Shrink Drum Wrapping Machine

Product Details:

- Type Automatic Shrink Drum Wrapping Machine

- Material Mild Steel Body with Powder Coated Finish

- Capacity 20-40 Drums per Hour

- Computerized Yes

- Automatic Grade Fully Automatic

- Control System PLC Controlled with HMI Touch Panel

- Shrink Speed 0-25 m/min (Adjustable)

- Click to View more

X

Automatic Shrink Drum Wrapping Machine Product Specifications

- Up to 500 mm

- 380V, 3 Phase, 50Hz

- Fully Automatic

- 0-25 m/min (Adjustable)

- Mild Steel Body with Powder Coated Finish

- Approx. 1250 Kg

- Automatic Shrink Drum Wrapping Machine

- PLC Controlled with HMI Touch Panel

- Industrial Blue & Grey

- Yes

- 3200 mm x 1600 mm x 2100 mm

- 6-8 Bar

- 20-40 Drums per Hour

Product Description

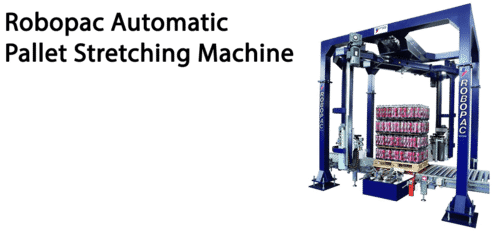

We are dealing in the manufacturing of Automatic Shrink Drum Wrapping Machine which is especially designed for the packaging lines of large scale product manufacturing industries to make a safe and secure wrapped packaging layer over the pelletized products such as water bottles, cold drink cans, wood panels and many others. It is equipped with an electrically powered rotating system which dispenses the wrapping sheet. The offered Automatic Shrink Drum Wrapping Machine has four support columns that provides higher stability.

Precision Shrink Wrapping for Industrial Drums

This machine delivers flawless shrink wrapping for drums through its advanced automation and PLC control, accommodating a wide range of drum sizes. The system ensures uniform and secure wrapping, optimizing packaging quality and operational efficiency. Its robust construction and modern finish offer longevity and resistance to industrial environments.

User-Friendly Touch Panel Control

The computerized HMI touch panel simplifies machine operation, allowing users to monitor, adjust, and maintain the process seamlessly. It enhances productivity and minimizes errors, making the machine accessible even to less experienced operators. Real-time alerts and diagnostics support quick troubleshooting.

Built-In Safety and Reliability Features

With integrated safety guards, emergency stop function, and overload protection, this machine prioritizes operator and workplace safety. The low noise level and sturdy build help maintain a comfortable and secure working atmosphere in demanding industrial settings.

FAQs of Automatic Shrink Drum Wrapping Machine:

Q: How does the Automatic Shrink Drum Wrapping Machine operate?

A: The machine uses a PLC-controlled system with a touch panel interface, automatically feeding drums onto a heavy-duty roller conveyor. Shrink film is applied and heated by stainless steel finned tubular heaters, then cooled with integrated fans, ensuring a uniform wrap around each drum.Q: What types of shrink film materials are compatible with this machine?

A: It supports PE, PVC, and POF shrink films with a thickness range of 40 to 120 microns, ensuring flexibility to meet various packaging requirements and material preferences.Q: Where is this machine typically used in the industrial sector?

A: This wrapping machine is utilized in manufacturing plants, chemical industries, and distribution centers across India where secure and efficient drum packaging is critical for storage and transport.Q: What safety features are included in the machine?

A: It incorporates emergency stop buttons, overload protection systems, and safety guards around moving parts to reduce risks and ensure operator safety during operation.Q: What is the benefit of using a heavy-duty roller conveyor in this system?

A: The heavy-duty roller conveyor facilitates the smooth and reliable movement of drums of varying sizes (50L to 250L), supporting higher throughput and preventing jams during continuous operation.Q: How often should maintenance be performed on the machine?

A: Routine checks are recommended every month, focusing on heaters, conveyors, and control systems. Preventive maintenance helps extend machine lifespan and minimizes unexpected downtime.Q: What are the advantages of computerized, fully automatic operation?

A: Computerized automatic control via PLC and HMI panel streamlines the wrapping process, improves consistency, reduces manual intervention, and enables rapid adjustments based on production demands.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free