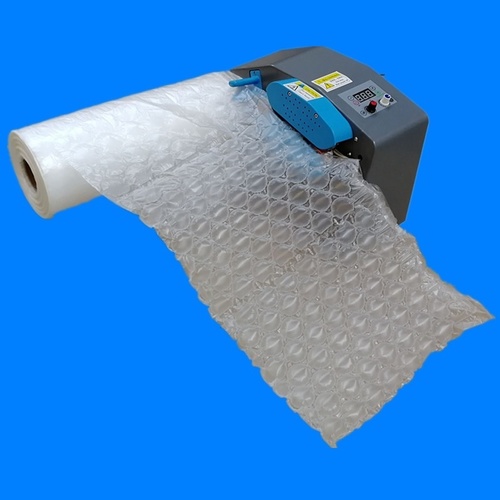

Air Cushion Machine

Product Details:

- Product Type Air Cushion Machine

- Material ABS Body with Metal Parts

- Type Automatic

- Style Desktop/Tabletop

- Packing Format Roll Film

- Hardness Rigid Frame

- Filling Capacity Variable, up to 12m/min

- Click to View more

X

Air Cushion Machine Price And Quantity

Air Cushion Machine Product Specifications

- Roll Film

- Minimal, 250W power rating

- 0.02-0.08 Mpa

- Black & Grey

- Automatic

- Rigid Frame

- Variable, up to 12m/min

- Air Cushion Machine

- High

- ABS Body with Metal Parts

- 410 x 200 x 210 mm

- Compact

- Desktop/Tabletop

Product Description

This Air Cushion Machine is ideal to attain maximum profits and businesses to get more packages with less down time. It is available with foolproof operation having active film web tracking feature. This is an easy-to-use plug in machine that loads film easily and swiftly for instant operation. Versatile film options of the machine ensure to fill air with high efficiency in three widths. This is available with different accessories to fit any need from small to large businesses. In addition to this, it can be used with different workstations and designs to maximize space and enhance output.

Air Cushion Machine features:

- Save high on materials, time and labor with automatic functions

- Compact design for east mounting and placing atop

- Easy to use with low and high inflation features

- Plug in and plug off of the machine ensures swift usage

Effortless Packaging for Modern Demands

With the Air Cushion Machine, businesses can streamline their packaging process while ensuring the secure shipment of goods. Its versatile film compatibility and rapid output make it ideal for handling high-volume orders. The digital touch-button interface allows operators to swiftly adjust settings, minimizing training time and maximizing operational productivity in fast-paced environments.

Precision and Efficiency in a Compact Design

Engineered for desktop or tabletop use, this air cushion machine boasts a compact footprint without compromising performance. The sturdy ABS body with metal parts offers durability, while the heat seal technology ensures reliable sealing. Setting up the machine requires minimal effortsimply load the roll film, select parameters, and enjoy dependable air cushion production every time.

Quiet, Safe, and User-Friendly Operation

During operation, the noise level remains under 60dB, creating a more comfortable workspace. Safety features, reliable electrical components, and rapid heating (ready in just 2-3 minutes) make the machine suitable for busy e-commerce warehouses and logistics centers in India and beyond. Its minimal air and power consumption contribute to cost-effective and sustainable packaging practices.

FAQs of Air Cushion Machine:

Q: How do I set up and operate the Air Cushion Machine?

A: To set up, place the machine on a stable surface, connect it to a 220V power supply, and load your compatible roll film (200mm or 400mm wide, 15-40 microns thick). Use the digital touch-button panel to select your desired settings. The machine heats up in 2-3 minutes and requires minimal air pressure (0.02-0.08 Mpa) to start producing air cushions.Q: What types and sizes of films are compatible with this machine?

A: This air cushion machine is compatible with roll films between 200mm and 400mm in width and film thickness ranging from 15 to 40 microns. It is ideal for various cushion film types used in protective packaging for e-commerce and logistics.Q: When is it beneficial to use an air cushion machine in packaging?

A: Air cushion machines are especially beneficial during periods of high-volume shipping or whenever you need to protect fragile goods in transit. The device ensures rapid and consistent production of cushioning materials, reducing manual packing time and helping prevent product damage.Q: Where is this machine best suited for installation and use?

A: Due to its compact size (410 x 200 x 210 mm) and desktop/tabletop style, the air cushion machine is perfect for use in e-commerce packaging stations, logistics centers, warehouses, and industrial workspaces across India and similar markets.Q: What is the process for changing the film roll or adjusting settings?

A: To change the film roll, switch off the machine, remove the empty roll, and install a new compatible roll. Adjust settings such as film width and sealing temperature using the digital, touch-button interface for seamless transitions between jobs.Q: How can using this machine benefit my business operations?

A: Utilizing the Air Cushion Machine enhances packing efficiency, reduces packaging material waste, lowers labor costs, and leads to safer product shipments. Its minimal power and air consumption (250W rating) and high output speed (up to 12m per minute) contribute to operational sustainability and cost savings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free